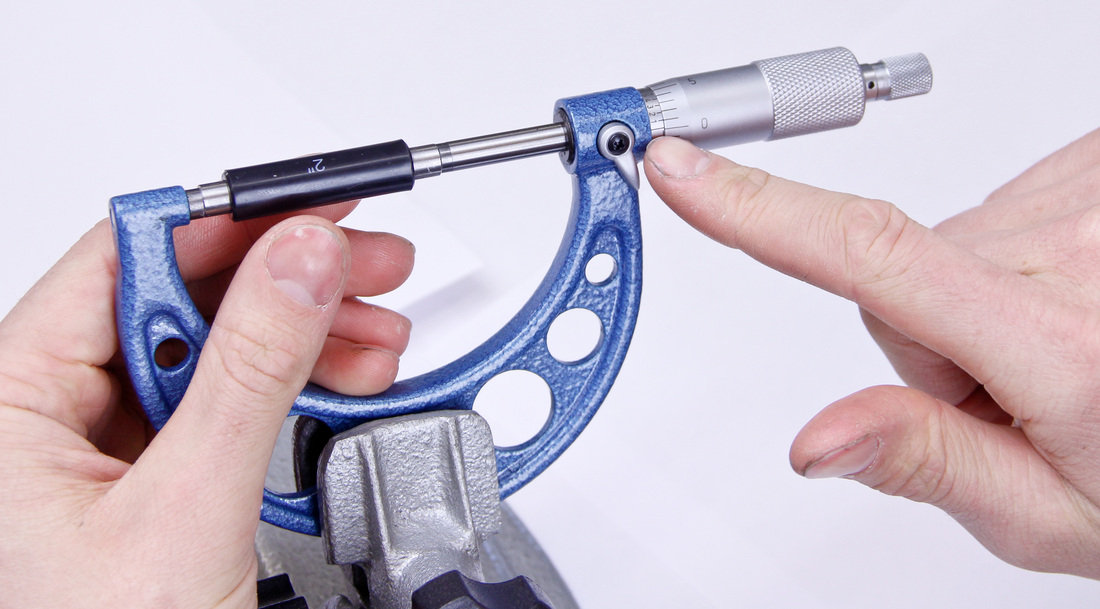

Ad Calibration and Repair1-3 Days Low Price Guarantee - ISO 17025. Micrometers feature a calibrated screw or thread which is located within the spindle and allows for the devices exceptional levels of measuring accuracy.

Replace low battery in a mitutoyo digital micrometer.

What tool is used to calibrate a micrometer. Ad Calibration and Repair1-3 Days Low Price Guarantee - ISO 17025. Calibration of your micrometer requires only a known length standard such as a gauge block an adjustment spanner and your micrometer. Additional supplies such as gage oil and task wipers will also come in handy but arent required.

What tool is used to calibrate a micrometer. A gage block is used to calibrate an unknown micrometer. The unknown is the micrometer and the known is the gage block being used.

This gage block must have a certificate of traceability to the National Institute of Standards and Technology NIST. Why are gauge blocks used for calibration of the micrometers. Gauge blocks are used because they are very accurate and they ensure the accuracy of the micrometer as well.

How to Use the Gauge Blocks. By following steps you will use a set of gauge blocks to calibrate the micrometer. You can use 5-gauge blocks of specific sizes that include 0210 0420 0605 0815 and 1 inch.

A gage block is used to calibrate an unknown micrometer. The unknown is the micrometer and the known is the gage block being used. This gage block must have a certificate of traceability to the National Institute of Standards and Technology NIST.

Speedy calibration checks can be with a set of gage blocks before each use. How to calibrate micrometers. When calibrating a micrometer the standard accuracy must be greater than a 41 ratio over the accuracy of the gage being calibrated.

The gage block must have a certificate of NIST traceability to have an accurate standard. The best way to calibrate an inside mic is with a calibration ring Gauge ring. These often cost more than the micrometer and for a wide range set you need to have a lot of them.

Most small shops dont keep a range on hand but either use alternative methods or send the tools out to a calibration specialist. The standards that we use to calibrate inside micrometers are as follows. Here are the steps I follow in calibrating an inside micrometer stick micrometer.

Calibration of inside micrometers using a linear measuring machine. A gage block is used to calibrate an unknown micrometer. The unknown is the micrometer and the known is the gage block being used.

Similarly you may ask how do you calibrate digital indicators. To calibrate you need a gauge stand a surface plate and appropriately sized. Outside Micrometer Calibration - How to Calibrate - Mitutoyo - YouTube.

What tool is generally used to calibrate a micrometer or check its accuracy. Guage block What precision measuring tool is used for measuring crankpin and main bearing journals for out-of-round wear. The micrometer screw gauge This normally has accuracy of 001 mm and is used to measure objects no more than a few millimetres across.

Likewise what tool is used to calibrate a micrometer. In this episode were going to discuss the calibration of the high accuracy mitutoyo mdh outside digital micrometer. Currently it supports the following monitoring systems.

A gage block is used to calibrate an unknown micrometer. Regular calibration intervals help ensure micrometer accuracy. Replace low battery in a mitutoyo digital micrometer.

So the question is how to calibrate either or both styles. My students will be doing a NIMS manual turning between centers hands on skill and the part has a 12-13 thread and a 34-16 thread. Both threads are 2A class and I dont want to send them out for inspection based on the fit of a.

Alliance Calibration specializes in multiple types of calibration including mechanical calibration which services a number of different mechanical instruments. One of the most common mechanical instruments that we receive for calibration is the micrometer. Micrometers otherwise known as micrometer screw gauges are essential measurement tools used by mechanical engineers machinists and workers in other technical trades.

They enable workers to take extremely fine measurements which may be displayed in. Micrometers feature a calibrated screw or thread which is located within the spindle and allows for the devices exceptional levels of measuring accuracy. The screw within the micrometer is used for the conversion of particularly small distances for measurement.

Calculate the distance of each stage micrometer division. Line up the micrometer with your eyepiece reticle scale bar. Count divisions and calculate size for that magnification.

Increase magnification and repeat calculations for each click stop. Gage blocks are a staple of machine shops measurement labs factories and anywhere else a precision measurement reference is needed. Gage blocks or gauge blocks can serve as a simple gonogo gage or be used to calibrate other equipment such as micrometers calipers or dial indicators.

Some micrometers use set screw and some use hook spanner. Which many companies have only the calibration people keep the hook spanners which often spanners disappear or get lost. Hook spanner type have some sort of friction mechanism so it dont slide turn too easy and go out of adjustment easy.

32 Use only those portions of the procedure applicable to the TI being calibrated. 33 Ensure the TI is clean and free from damage which could affect calibration or use. 34 The TI must be brought into the calibration area at least 8 hours prior to beginning the calibration.

35 The temperature of the calibration area must be within 73 6 F. Ad Calibration and Repair1-3 Days Low Price Guarantee - ISO 17025.