The top torch is a welding torch and the bottom is a cutting torch Welding torch edit. One Piece Special Application Series 1 Type HDNL Extra length.

1Type GPN Hand machine torch cutting.

Types of cutting torches. Oxy-acetylene torches cut metal by using oxygen to burn metal. An acetylene flame is used to heat the metal to ignition temperature and then adds oxygen to increase the temperature of the flame and burn away the metal to be removed. The heat of the oxygen flame causes elements in the metal under the flame to oxidize in a chemical reaction.

Heavy Duty Cutting Torch Victor Type Oxygen Propane Acetylene Welding Torches Flame Torch Handle Cutting Attachment w Propane Tip and Acetylene Tip. Types of Cutting Torches There are two standard metal cutting techniques. Plasma and oxy-fuel cutting.

Both methods have their advantages and disadvantages but choosing the best fit for your job depends on quite a few factors. This article covers the standard type of cutting torch which is an acetylene torch set up. Pure oxygen is used for the cutting jet and its mixed with either acetylene propane or commercial gas to.

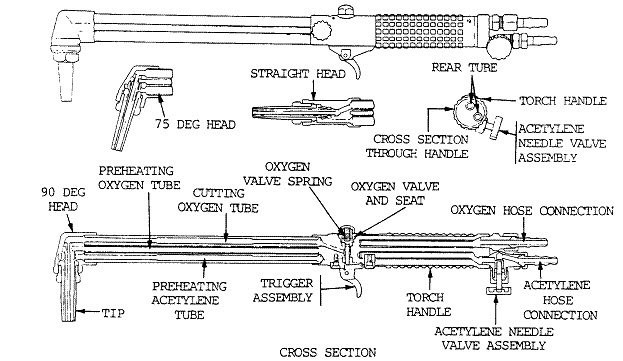

See Chapters 13 and 14 for additional information. There are two types of welding and cutting torches commonly used. They are the positive-pressure type also known as an equal-pressure type or medium-pressure type torch and the injector type.

It can be an acetylene cutting torch an oxy cutting torch or a cutting torch for different fuels such as propane butane natural gas and liquefied petroleum gas. The advantage of having such a torch is it allows you to pick different fuels but uses the same torch. Soldering brazing and welding.

For each type of bond there is a specific type of torch and knowing which to use for a specific task is essential. Torches come in many different types and use a variety of fuels and a multitude of accessories but there are three basic types that you need to be familiar with. We are offering a wide range of CuttersThese products are used for industrial use and are easy to handle and workThese products are offered to our clients at variable market leading pricesNew generation Nozzle Mixing Technology for new standards in Safety and Efficiency Light weight Cutters are easy to handle and can withstand rough usage for longer time.

Two basic types of torches are positive pressure type and low pressure or injector type. The top torch is a welding torch and the bottom is a cutting torch Welding torch edit. Cutting Torches and Accessories.

Gas cutting and welding torches also known as oxy-fuel torches or oxy-acetylene torches use fuel gas and oxygen to heat and cut through metal workpieces. Cutting torches efficiently cut through thick steel and stainless steel. The oxy-fuel cutting torch kit is inexpensive making it ideal for those just starting to learn how to cut metal or work on small-to-medium projects.

You can use it manually or mechanized. This industrial thermal cutting process can work on metals with thicknesses of 05 mm to 250 mm. How exactly does this metal cutting torch work.

Type Style 25LMin 250bar 25MPa 10kgfCm2 W22-14 Cga540 510 Established in 1987 Hakin is one of the biggest manufacturers of pressure gauge in China and a specialized producer in the field of gas regulator cutting torch welding torch thermometer. Compared to a plasma cutter what the cutting torch gives up in precision it more than makes up with its ability to cut far thicker materials. A heavy duty plasma cutter might handle material between 2 and 3 thick.

The oxyfuel cutting torch will easily cut through plate thats 6 thick or greater. Its also relatively inexpensive. Wholesale Types Of Cutting Torches Find 67 types of cutting torches products from 41 manufacturers suppliers at EC21.

Choose quality types of cutting torches manufacturers suppliers exporters now. Silver Steel- is another alloy that has been shown to work well in this machine. Expanded Steel- is another type of metal that can be cut with a plasma cutter.

Iron- which is commonly found in the construction industry as rebar or rods is also capable of being cut with a plasma cutter. Select the tip style for the fuel gas you are using and metal typecondition. Cutting tip designs vary based on fuel gas and application.

A 1 piece tip is typically used for oxygen-acetylene use and a 2 piece tip is used for oxygen-alternate fuel gas natural gas propane propylene etc use. Ive heard many fabricators and steelworkers ask this. Their efficiency is so much associated with the type and thickness of materials and power resources that many of us especially the beginners find it hard to decide if a plasma cutter is preferable to a cutting torch a century-old system that we call oxy-fuel torch these days.

There are two types of DC torches. In non-transferred DC torches the electrodes are inside the bodyhousing of the torch itself creating the arc there. Again Im absolutely clueless about the details of plasma cutting machines and torches I dont even know what the numbers on the machines meant.

I really hope to get some information soon. Thank you in advance for your help. 07-21-2017 0225 AM 2.

1Type GPN Hand machine torch cutting. Two Piece General Purpose Series 3 Type GPN Hand torch cutting. Series 3 for small cutting head One Piece Special Application Series 1 Type HDN Mill and foundry scrap cutting under severe conditions.

One Piece Special Application Series 1 Type HDNL Extra length. When oxy-cutting managing the oxygen flow rate will determine what kind of cut is made. Torch cutting with too much oxygen both adds to the overall cost and results in a wide cut with curved edges rather than the sharp clean edges that are desired when cutting with a torch.