This new type of bushing constantly lubricates itself and the metal S-camshaft reducing friction and preventing wear of the metal surface. Remove both retainer clipssnap rings from grooves on s-cam shaft on either side of bushing housing brake spider.

Install camshaft seals into the spider.

How to replace s cam bushings. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. Replacing S-Cams And Bushings - YouTube. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

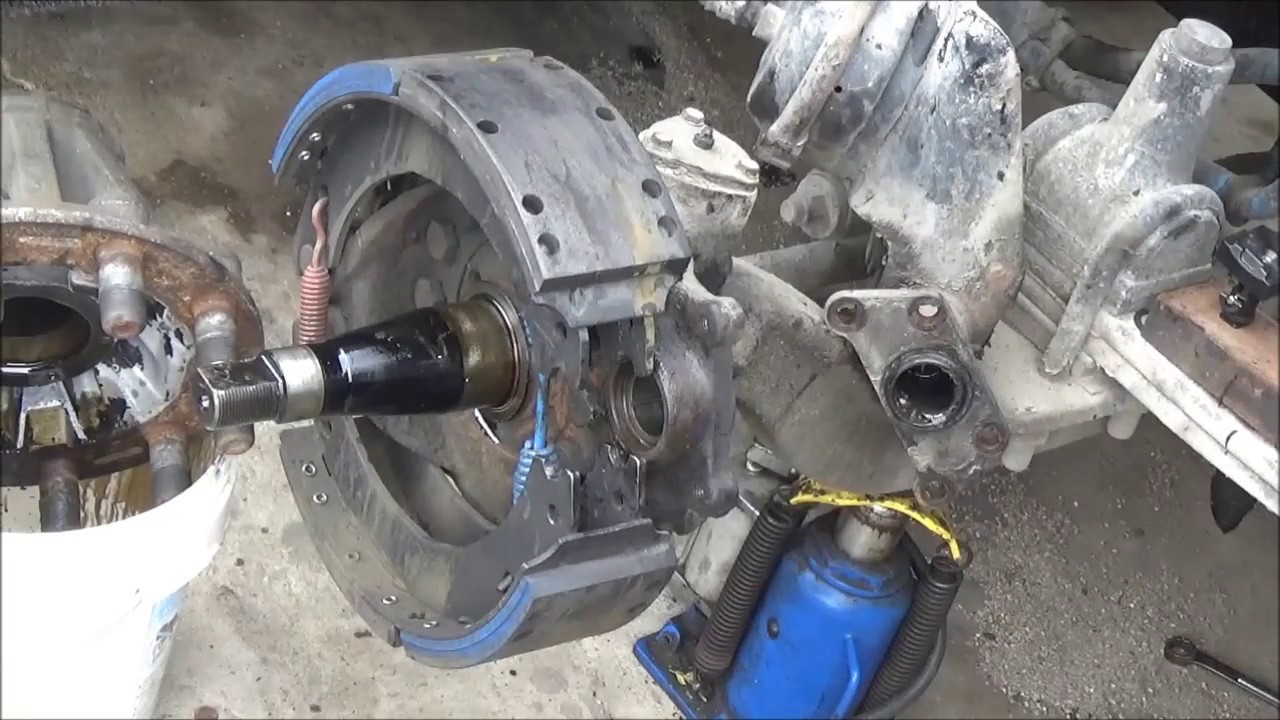

Old Bushing Removal 1. Lift and support axle remove wheels brake drum and brake shoes. Remove both retainer clipssnap rings from grooves on s-cam shaft on either side of bushing housing brake spider.

Slide shaft outboard and move flat washers to access both grease seals in bushing housing. Install new camshaft bushing. Ream bushing to 15051515 if required.

Install camshaft seals into the spider. When installing camshaft seals the seal on the slack adjuster side is installed with seal facing into spider. This allows grease to purge outside the brake assembly when greasing the camshaft bushing.

It also aids to avoid damage. Put the slack adjuster back on placing a washer between the adjuster and the cam tube and another on the cam head. This will help keep dirt and contaminants out of the bushings and seals.

Its not going to hurt to try tho–rightcould try and get the grease seal out–but then your s-cam bushing will be inset about a 14 inch or so—so no room to drill and put a small screw in to pull it out—hmmm i would see if you could drive the seal in further maybe with a. Ironhead Cam Cover Bushing Replacement. This has seen some run time.

When I pulled it off the motor the pinion bushing fell off. Was chromed at one time in its life. Platers did a poor job of protecting the bushings from flash plating and they got a dose of chrome.

I striped the chrome and intend to powdercoat the cover. UHB800-CAM APPLICATION IDENTIFICATION INFORMATION In order to select the correct S-cam part number you must know the following information. Steer Drive or Trailer Make of axle manufacturer Suspension model when noted 2 Cam length.

Measurement from under cam head to beginning of lock ring groove at camshaft tip. One of these bushing end seals 74 will be seated on the shaft 36 on either side of the bushing 54 between the bushing and the aperture in the adjacent housing half. In the preferred embodiment of the present invention the bushing end seals 74 are double seal surface D-rings.

The bushing end seals are seatable in the shaft 36. Remove the dial indicator from the inboard end of the cam and rotate it over to the cam head then manually move the cam head up and down to measure the radial play. If the radial play is 0030 of an inch or more the cam bushing or camshaft is worn and needs to be replaced.

Now you can remove and replace the S-Cam bushing on air brake equipped trailers without removing the wheel hub or replacing the wheel seal. Save time and money yourself and for your customer with this innovative durable tool. Offer S-Cam replacement with every brake job.

Remove bolts on S-Cam bushings and pull the S-Cam. Install the seals for the new bushings. Use anti-seize on spots where the bushings ride.

Install outer bushing and washers on S-Cam. Slide S-cam in the bushing put bolts in and tighten. Put the slack adjuster back on and grease the S-Cam 12.

Put the drums and wheels back on. The New Etcom No Grease S-Cam Composite bushings have dry-type lubricants mixed into the plastic so that it is always available on the bushing surface. This new type of bushing constantly lubricates itself and the metal S-camshaft reducing friction and preventing wear of the metal surface.

As an added benefit the special lubricants in the new non-meltable plastic bushings will actually polish the surface. Honestly never heard of reaming s cam bushings either. But then again and I havent been around alot of em I have never seen anything but nylon or delrin or whatever it is- non metallic s cam bushings.

The dimensions you are giving are about dead nuts for bushings made to be reamed. Worse case scenario- get an 1500 flap disc at lowes or. INSTALLING S-CAM 1 The groove filler prevents damage to the seals during installation of the S-Cam.

Remove filler after installing S-Cam. 2 Use the widest spacer that fits between the cam tube and the snap ring groove 3 Install the snap ring 4 There should be no lateral movement of the S. Been a while but the seals are backwards.

They dont go flat side out to scam they go dented side. There to seal the crap from getting into the scam bushings. Over greasing will blow the seals out.

And well more failure. So there wording would be correct. The seal goes towards the bushing.

Im ordering parts to replace all my rear S-cams and all the bushings. Peterbilt trying to sell me meritor nylon cam bushings and said thats all they had and are better than the brass. I find that hard to believe.

Especially on a heavy local truck. I replaced the outer bushings last rear when i replaced all my slack adjusters and brake chambers. What should you do if you have a flat spot on the S-cam face.

Most brake linings are designed to perform equally well under a wide range of operating conditions. When selecting replacement brake shoe linings you should consider _____. Operating terrain and conditions.

Now you can remove and replace the S-Cam bushing on air brake equipped trailers without removing the wheel hub or replacing the wheel seal. Save time and money yourself and for your customer with this innovative durable tool. Offer S-Cam replacement with every brake job.

1-78 OD and 1-58 ID. If youre replacing the cam cover bushings replace the one in the engine case too. The idler gear bushings need to be finish-reamed to size but do not need to be line-reamed.

Cam Bushing Removal Tool. There is a Harley-specific tool called a crankcase cam-gear shaft bushing remover. This tool carries part number 96760-36 and has only one.

I use a universal cam bearing installerremover. A cam bearing is basically the same as a trans bushing. TH350s are rougher on bushings due to design so ensuring the bushings are in good shape is important to keep everything riding on center.