Remedy Contact your FANUC service center. Jie Huang root at linuxsand dot info.

Fanuc alarm codes also called error codes or fault codes are essentially the way Fanuc and other CNC controls issue error messages.

Fanuc robot error codes. 28 FANUC robot programming error codes and what they mean - DIY-Robotics. Identify your FANUC robot programming error codes to keep it performing at its best for years to come. Here are 28 common FANUC robot error codes.

What are Fanuc Alarm Codes. Fanuc alarm codes also called error codes or fault codes are essentially the way Fanuc and other CNC controls issue error messages. An alarm code may indicate a problem with the CNC machine mechanical or electrical or with the g-code program the machine has loaded.

Diagnosis and Correction of Fanuc Alarm Codes. Wtfanuc curl httplinuxsandinfofanuccode-api1 You can then get error codes by simply typing. Wtfanuc SRVO-063 Faults errors alarms whatever you want to call them are inevitable but knowing how to look up what they really mean and how to fix them will.

52 rows Fanuc Servo Amplifier 400 Alarm Codes. Alarm Code Message Description. A FANUC alarm code also called a FANUC fault or error code is how a CNC control indicates there is a problem.

This error message could indicate issues with either the machine itself be that electric or mechanical. The FANUC error code might also indicate an issue with the g-code program. 70 rows Motor sensor one-rotation signal detection error.

Motor sensor one-rotation signal not. SRVO-063 or SRVO 063 or srvo-063 or srvo 063. Results are based on R-30iB Controller.

Jie Huang root at linuxsand dot info. Other FANUC Tools I made. I am currently working with the FANUC LR Mate 200iC5L and R-30iA Controller.

The robot once used in onther project. Old robot new install. The following error messages occur.

Axis6 SRVO-062 BZAL alarmGroup1. Axis5 SRVO-062 BZAL alarmGroup1. To be able to pass from P2 to P3 the robot turn the joint 6 counter clock wise of another 120deg J6 value 360 deg because the robot try to reduce the angular displacement when its the time to go from P3 to P1 the joint 6 goes counter clock wise.

To ensure the safety of user and prevent damage to the machine this manual indicates each precaution on safety with Warning or Caution according to its severity. Supplementary information is indicated by Note. Read the contents of each Warning Caution and Note before attempting to use the oscillator.

When there is a fault in the system you will see the information appear in the top box of the teach pendant. In this example there is a Fault with the fault code of SRVO-002 and a note saying Teach Pendant E-stop. To find out more about this fault Select MENU and arrow down to 4.

You will probably have to adjust the memory configuration in your robot controller. ERROR CODES MARRBERCD04121E REV B. 3129 APSH-008 FAULT must be reset.

A fault has ocurred so the operation requested cannot be performed. SRVO-062 BZAL alarmGroupd Axisd Cause. This alarm is issued when the battery for backing up the absolute position data of the Pulsecoder is not connected or is empty.

The battery cable inside the robot might have become disconnected. B-83124EN-601 R-30AR-30A Mate CONTROLLER. Alarm Code List For series 7DA47DA5 Or i gi nal Inst r uct i ons Before using the Robot be sure to read the FANUC Robot Safety Manual B-80687EN and understand the content.

No part of this manual may be reproduced in any form. All specifications and designs are subject to change without notice. CNTR Error Codes CNTR-004 WARN No cnir pointer Cause Internal software error.

Remedy Contact your FANUC service center. CNTR-005 WARN Wrong CN AxisN1 or N2 Gi Cause The number of the continuous rotation axis is invalid. Remedy Set a valid axis number.

CNTR-006 WARN Unable to Allocate Memory Cause Internal software error. User model number 0. When CPU1 detects the error this is 1.

When CPU2 detects the error this is 1. The solution is if the robot is actually out of the safe zone then you have to press SHIFT key along with RESET key and then jog your FANUC to. FANUC ERROR codes and alarms for Fanuc drives.

Check for LEDs lit on drive control PCBs or numbersletters such as AL11 in the multi section 7 segment LED displays. DC AXIS unit alarms. FANUC ROBOTS ALARMS CODESFull description.

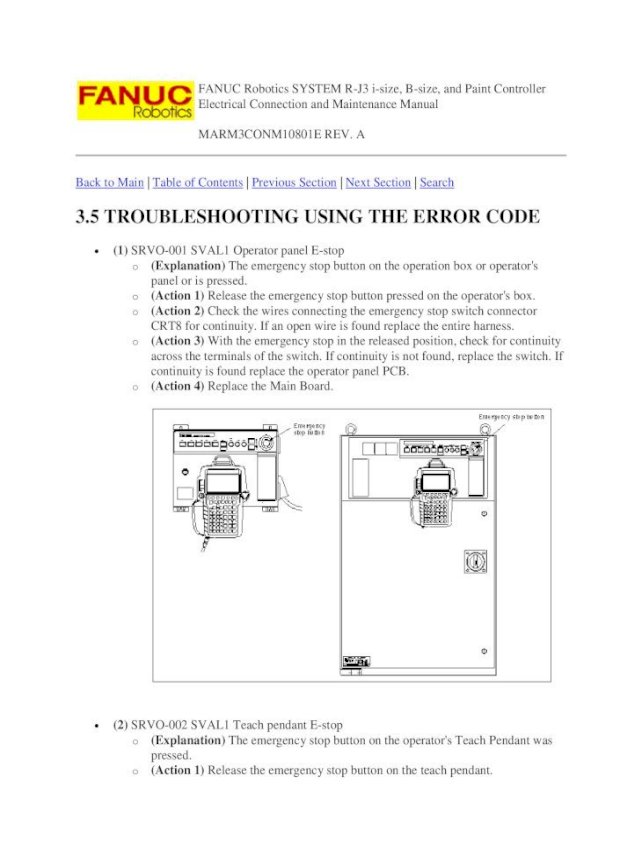

Remedy Either delete any unnecessary jobs manually or increase the queue size. APSH-020 WARN Job queue is. FANUC Robotics SYSTEM R-J3 Troubleshooting and Maintenance Manual - FANUC Robotics SYSTEM R-J3 Troubleshooting and Maintenance Manual - Download as FANUC Robotics SYSTEM R-J3 35 TROUBLESHOOTING USING THE ERROR CODE PROJECTORS - Panasonic - Panasonic will not use information collected here for marketing or promotional purposes beyond the scope of.

CMCC-008 WARN Unsupported function code. This is an internal system error. Cold start the controller by powering off and then powering on while pressing the reset key.

If the error is not cleared document the events that led to the error and call the Fanuc Robotics Hotline. The emergency stop board has the following fuses. FUSE1 For protecting 24EXT to the emergency stop circuit A60L-0001-004610 FUSE2 For protecting 24V to the teach pendant A60L-0001-004610 FUSE3 For protection of the 24V A60L-0001-004620 FU1 and.

Module SevenError and Fault Recovery. SRVO-014 WARN Fan motor abnormal Cause. A fan motor in the control unit is abnormal.

Check the fan motors and fan motor connection cables. Replace any faulty fan motors andor cablesSRVO-015 SERVO System over heat Cause. The temperature of the.

Even though the n-th axis axis 1-8 READY signal MCON went off the servo amplifier READY signal DRDY is still on. Or when the power was turned on DRDY went on even though MCON was off. ZERO POINT RETURN FAULT.

Position control system fault.